Production process & positioning

An innovative & decarbonized production line

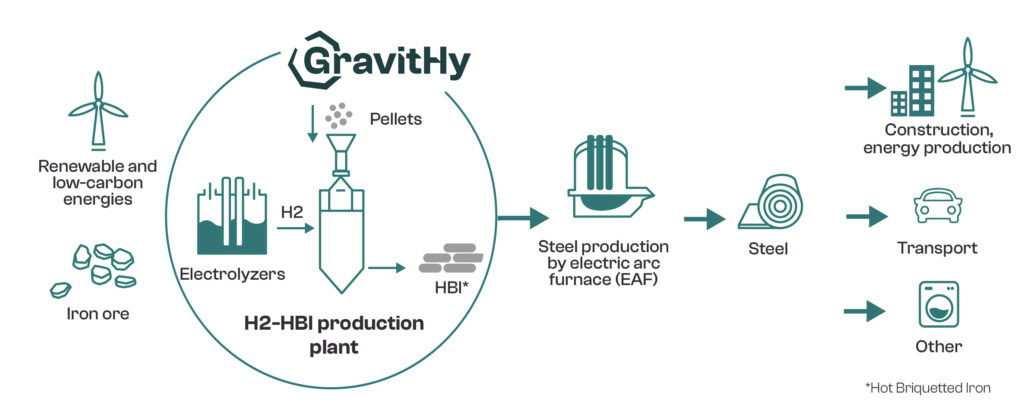

GravitHy implements an advanced industrial process to produce Direct Reduced Iron (DRI/HBI) from low-carbon hydrogen. This process allows replacing the coal used in the blast furnaces with a clean and sustainable solution, reducing up to 90% of CO₂ emissions related to iron production.

01/

Import of iron ore

The ore (pellets), is transported by sea to the Fos-sur-Mer mineral terminal. About 3 million tonnes per year are planned.

02/

Low-carbon hydrogen production

GravitHy will produce up to 120,000 tons of hydrogen per year, via the electrolysis of water, powered by renewable and low-carbon electricity. The installed capacity of the electrolyzers will reach up to 720 MW, making it the largest installation ever built in France.

03/

Direct reduction of ore

Iron ore and hydrogen are injected into the DRI tower (or reactor) for direct reduction of iron ore. The reaction between hydrogen and iron pellets results in metallic iron, without carbon combustion. 2Mt/year will be produced by the GravitHy’s plant in Fos sur Mer.

This innovative process allows the production of iron to be decoupled from that of steel, allowing increased industrial flexibility.

04/

Transformation to HBI

Reduced iron is compacted as HBI (Hot Briquetted Iron), facilitating its transport and use by European steelmakers.

An innovative positioning in the steel value chain

Traditionally, steel production is based on an integrated chain: iron ore is processed into cast iron in a blast furnace and then converted into steel in a converter. This model is energy-consuming, CO₂ emitting, and not very flexible.

We introduce an industrial break by dissociating the production of iron (DRI/HBI) from steel production. This approach enables the creation of a new autonomous link in the value chain: a ready-to-use low-carbon iron, sold as a commodity to steelmakers.

A new market for HBI

We offer HBI (Hot Briquetted Iron) as a standardized product, available on the European market:

- Intermediate product between the ore and the steel, usable directly in electric furnaces.

- Supplement to scrap, whose quality and availability can vary.

- Transportable and exportable, with a reduced carbon footprint.

- Emerging market in Europe, in response to decarbonization objectives.

Low-carbon hydrogen

Hydrogen, the cornerstone of iron decarbonization

We will produce and use low-carbon hydrogen to produce our reduced iron (HBI), replacing natural gas or coal used in traditional processes. This technological choice enables ~90% reduction in CO₂ emissions related to the production of metallic iron.

How it works

The process is based on water electrolysis, which involves separating water molecules (H2O) into hydrogen (H2) and oxygen (O2) using an electric current. When this electricity is renewable or low-carbon, the hydrogen produced is itself low-carbon.

This hydrogen is then injected into a direct reduction reactor (or DRI tower), where it reacts with iron ore to extract oxygen, thereby producing metallic iron without carbon combustion.

Purpose

Our purpose A new industry standard As a future European leader in low-carbon iron production, our model is based on collaboration and a strong commitment to local ecosystems. We position …

Low-carbon iron

GravitHy’s Hot Briquetted Iron An industrial convenience for greener steel Low-carbon iron for greener steel We produce direct reduced iron by using low-carbon hydrogen. Our HBI (Hot Briquetted Iron), is …

GravitHy Fos-sur-Mer: a pioneering plant on a European scale

Key figures 3D of the GravitHy factory in Fos-sur-Mer, by the consortium Enia Architectes, Rougerie+Tangram. A strategic location in the heart of southern France Our future industrial site contributes to …