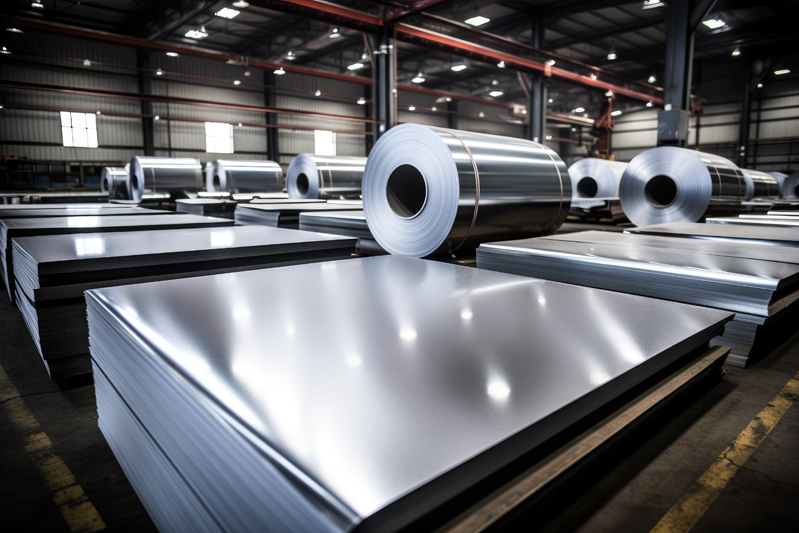

GravitHy’s Hot Briquetted Iron

An industrial convenience for greener steel

Low-carbon iron for greener steel

We produce direct reduced iron by using low-carbon hydrogen. Our HBI (Hot Briquetted Iron), is compact and stable, easily transportable for steelmakers to use in their green steel production process.

It is a sustainable alternative to traditional processes, the majority of which are based on the use of coal in blast furnaces. Our process thus reduces CO₂ emissions related to steel production by ~90%. The carbon footprint of our HBI is estimated between 50 and 120 kg CO₂ per tonne, with a target at 50 kg CO₂/t according to electricity supply.

Immediate benefits for steelmakers

- Compatibility with existing steelmaking (electric arc furnaces).

- Immediate reduction of CO₂ emissions, without heavy transformation of the installations for steelmakers.

- A supply flexibility for steelmakers: HBI form adapted to transport and export.

- Gradually adapt their material mix, combining scrap and HBI according to their needs.

- Access to green steel for demanding sectors: automotive, construction, energy, defence etc. without heavy transformation of their industrial tool.

Market, end users and prospects

A growing need for low-carbon iron

Global demand for low-carbon steel is growing rapidly, driven by the automotive, construction, energy, infrastructure and transport sectors. In Europe, this dynamic is reinforced by climate policies (CBAM, ETS), carbon neutrality objectives, and the commitments of major contractors to reduce their Scope 3 emissions.

To produce this green steel, steelmakers need low-carbon raw materials – notably HBI (Hot Briquetted Iron). This product is becoming a strategic commodity, in a context of scarcity of scrap and the rise of electric arc furnaces (EAF).

An industrial response to a massive need

Our first production site in Fos-sur-Mer will produce 2 million tons of HBI per year, almost the equivalent of one Eiffel Tower per day.

This low carbon iron:

- Is compatible with existing electric arc furnaces.

- Reduces CO₂ emissions from steel production by ~90%.

- Offers consistent quality, unlike scrap.

- Is easily transportable and exportable, in the form of compact briquettes.

Applications & end users

Our Hot Briquetted Iron (HBI) is designed for steelmakers and industrial players engaged in decarbonation. If you want to reduce your emissions while ensuring optimal quality, our team is here to support you.

Need to know more? Let’s talk about it!

European steelmakers

In transition to green steel.

Car manufacturers

Committed to reducing their carbon footprint.

Construction players

Developing low-carbon projects.

Energy players

(Wind, nuclear, solar) for their metal structures.

Transport and aeronautics sectors

For decarbonized steel components.